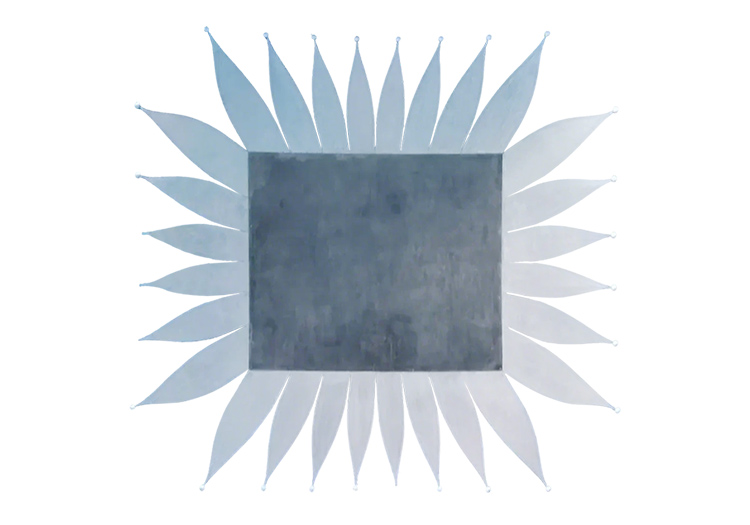

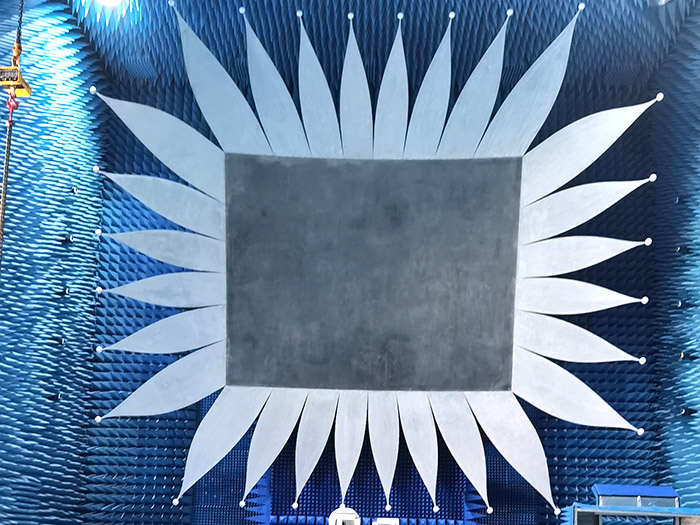

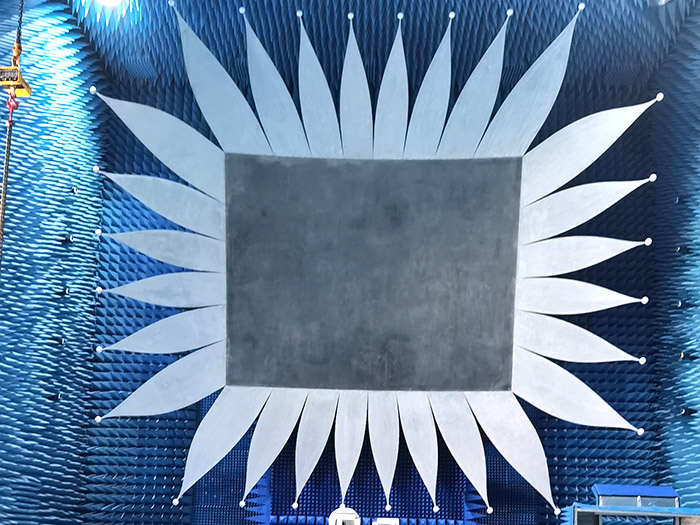

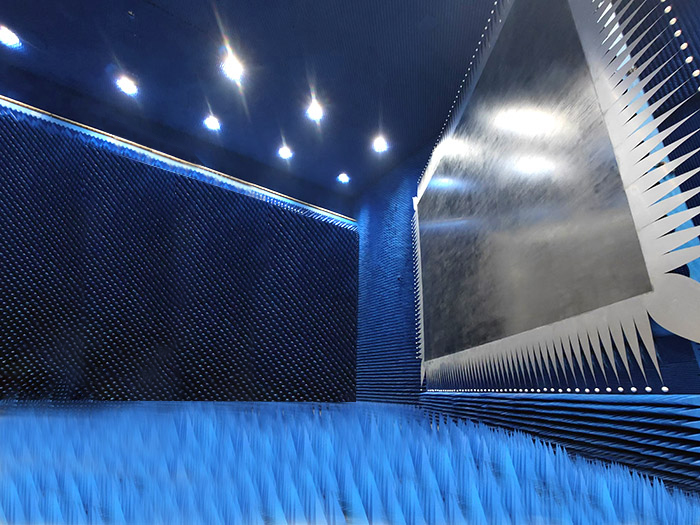

Large Serrated Reflector Compact Range Antenna Subsystem

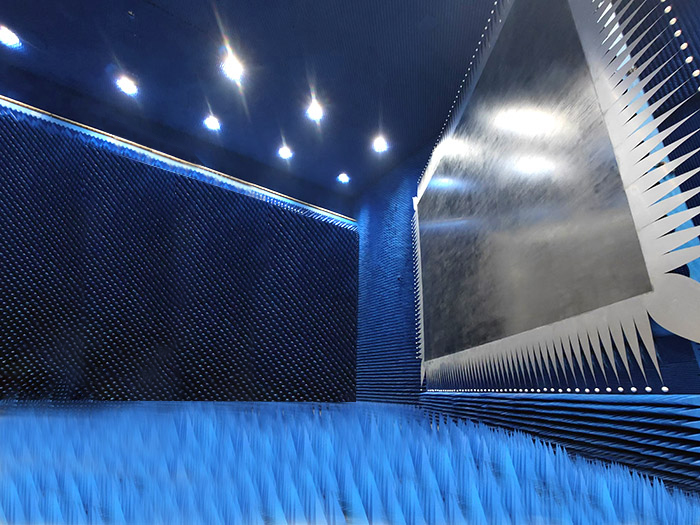

The reflector surface is manufactured using a precision machining process,with individual panels covering up to 120m²,offering high surface accuracy,low thermal expansion coefficient,and minimal thermal deformation.The feed turntable supports automated feed switching,features six degrees of freedom(6-DOF)adjustment and locking mechanisms,and delivers high repeatability and stability.The mounting bracket can be customized to fit specific anechoic chamber configurations,and the large compact range system provides tailored requirements for base support load capacity and interface dimensions.The antenna subsystem boasts a simple structure,short development cycles,and low operational/maintenance costs.

Consultation