Aviation Products

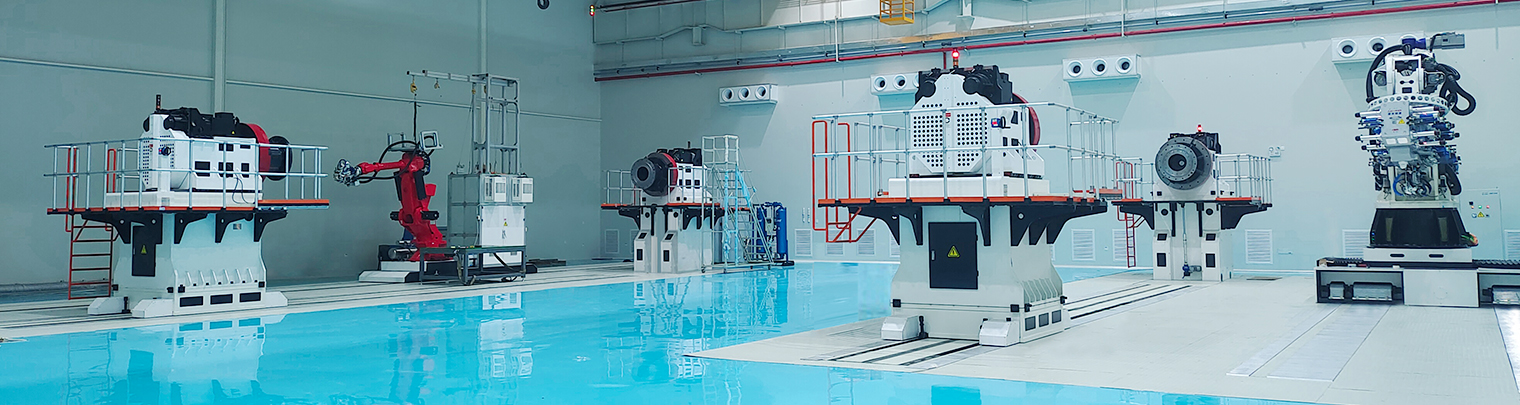

The company has established end-to-end capabilities in aviation product development, covering design, simulation, manufacturing, assembly, inspection, and validation. Key infrastructure includes: A 45,000-square-meter smart composite manufacturing center; 12,000 square-meter climate-controlled cleanrooms with temperature/humidity regulation and ISO Class 8 cleanliness. Core Equipment Portfolio: 11 Automated Fiber Placement (AFP)/Automated Tape Laying (ATL) systems: 8 robotic AFP units, 3 gantry-type AFP/ATL machines (max. working range: 36 meters), 3 composite-dedicated 5-axis machining centers, 9 autoclaves, including a large-scale unit (8m diameter × 36m length).

This infrastructure supports full-cycle R&D and production of aviation composites, encompassing, Automated/hand layup, Curing, Precision machining, Adhesive bonding, assembly, Non-destructive inspection, Performance testing.